Standardised and modular medium head power solution

Standardised and modular medium head power solution

| Net Head | 81.38 m |

| Discharge (per module) | 1.600 m³/s |

| Power Output (per module) | 1192 kW |

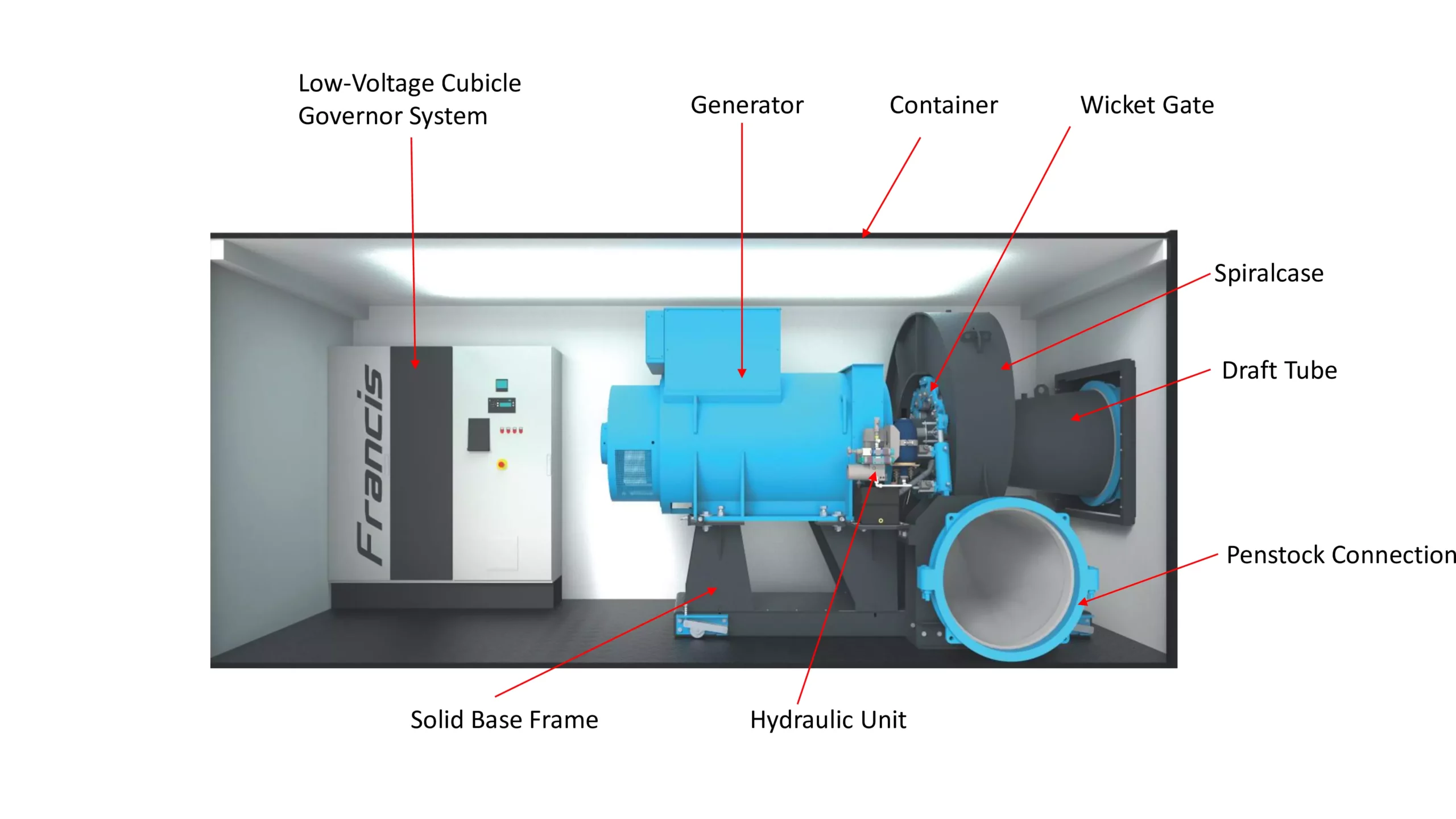

The Francis Container Power Solution (FCPS) corresponds to a classic medium pressure concept for the lower power range. In Hydro4U, the structural part of the plant is rigorously reduced and standardised by eliminating the traditional powerhouse and installing the turbines in a prefabricated container. This offers the greatest possible degree of pre-assembly by reducing the installation efforts on the construction site to a minimum – concrete foundations and a mobile crane are enough to install and commission the mobile container solution and its equipment in a few days. Thus, installation time as well as civil construction and maintenance costs are reduced. The container concept and the machines already exist as plans and have been manufactured as prototypes.

Another important characteristic of the Hydro4U concept is to standardise and modularise FCPS components. Whereas the design of a conventional small hydro power plant is adapted to the specific data of the site, project partner Global Hydro will develop a concept to use standardised modules with a low number of different types and sizes for the runner, the spiral case, the base frame and the generator speed. These standardised components shall be combined to a FCPS unit for a specific site and therefore reduce engineering and production costs. This concept of standardisation will also be extended to penstock and water intake. This will provide a competitive concept for medium head FCPS within Central Asia.

Site & Method of selection: Shakimardan

Geo facts:

The site in Shakimardan, located on the Koksu river in an Uzbek enclave within Kyrgyzstan, has been identified to be suitable for the demonstration of the FCPS solution developed by Global Hydro Energy. The enclave suffers from regular power outages because the supply depends on electricity from Kyrgyzstan. The hydropower station would allow to maintain a reliable electricity grid. There is an already existing intake structure followed by a 2.5 km long buried penstock which was built in the 1980’s but eventually abandoned. These structures will be repaired and retrofitted and used for the planned hydropower station in close collaboration with the state utility Uzbekgidroenergo. The hydrological situation is very favorable because of two natural lakes upstream of the intake formed by natural landslides. The lakes are balancing rapid flow fluctuations and the seepage flow through the earth embankment dams keeps water temperatures above freezing all year around. The study of various climate change scenarios showed that the hydrological regime will not change significantly over the next four decades, the expected lifetime of the turbines. The rated flow for the turbines will be 3.2 m³/s in total, considering the environmental flow that has to be a release in the dewatered reach. The water is diverted directly into the penstock and reaches a gross head of approximately 100 m and a rated capacity of more than 2 MW. The power plant can be operated all year around including the coldest winter months where it still reaches almost one third of the rated capacity. The annual energy generation is around 13 GWh. Two Francis container units of equal size will be installed.

The overall sustainability of the project has been generally evaluated during several site visits. The operation of the hydropower plant would lead to a reduction of the flow of water in the dewatered reach. To compensate this, sufficient environmental flows will have to be released at the intake. An artificial migration barrier is presently existing several hundred meters downstream of the intake and fish were not found upstream of this waterfall although there is suitable habitat. As part of the construction of the hydropower plant some fish pass over this artificial migration barrier will be installed and also a fish ladder will allow upstream migration across the intake. A fine fish screen will keep fish from entering the penstock and thus allow downstream migration as well. As a consequence, several kilometers of additional habitat for snow trout will be available once the hydropower plant is built and operating.

The construction and operation of the small hydropower plant will provide significant benefits for the inhabitants of the two villages in the enclave because they will have a stable electricity supply, with a sufficiently high baseload even during the winter months to cover at least the essential needs. It is therefore planned that the power plant can operate in island mode as well as grid connected.

There will be no effect of the hydropower plant on river reaches downstream of the power containers or the confluence of Koksu and Aksu rivers.

On site challenges:

SOLUTION FACTSHEET of project result:

Videos:

Selected Updates from News & Events: