Muhr Group relies on scalable approach for the new hydroshaft power plant

December 5, 2022

During the last 12 months, the Muhr Group worked on the scalable design approach for the new hydroshaft power plant. Now they finalised all the relevant steps and submitted the associated final report, the time was right for an interim summary.

The assessment is consistently positive: Very little time has passed between the first prototype design and an achievement of product readiness level. To have increased the marketability of the hydroshaft power plant to such an extent – and so early in the product’s life cycle – is a great success for Muhr. The level of marketability achieved is made possible through Muhr’s scalable design approach.

From Concept Study to CAD Model

The aim of the design work was to achieve a level of optimization that would allow to meet the ambitious goals of the Hydro4U project (funded under the Horizon 2020 research programme). Muhr started with concept studies, which were further developed into CAD models, based also on feasibility tests and FEM simulations. These 3D models are much more than three-dimensional technical drawings. They were designed in such a way that they can be used for cost calculation, procurement, and manufacturing of the planned power plants. The scalable approach allows power plants to be designed and implemented in less than a year.

All products were prepared for future use based on lessons learned from the operation of the first two commercial power plants. The first two power plants are also equipped by Muhr and successfully generate green energy for about 900 households.

The Muhr Group’s involvement in Hydro4U

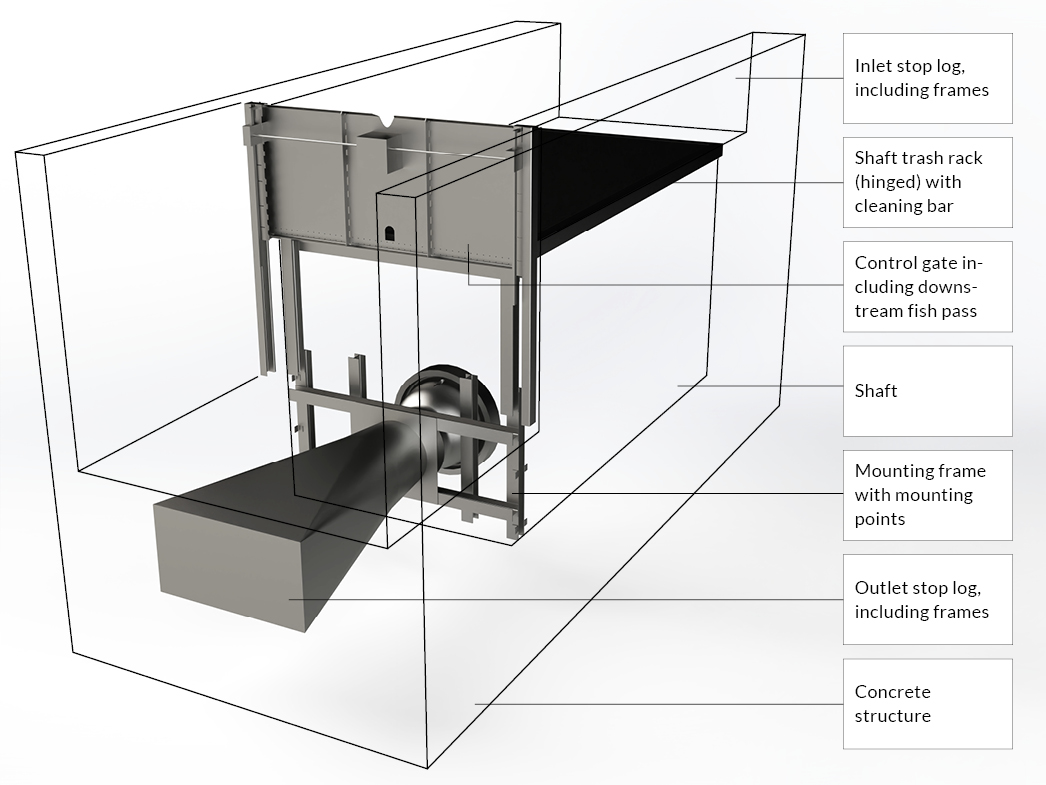

The Muhr Group supplies the following products for the new plant type hydroshaft power plant:

- Inlet and outlet stop log including frames, for damming up the power plant in case of maintenance work.

- Control gate including downstream fish pass for regulating the dam height, allowing the turbine to produce power as efficiently as possible. The control gate also serves as a flushing opening for the passage of bedload in the river course, as a fish pass for fish and other aquatic creatures downstream of the power plant, and as an opening of the discharge cross-section in the event of a flood.

- Shaft trash rack with cleaning bar for cleaning the turbine water (to protect the turbine) and the shaft trash rack, which ensures the efficiency of power generation.

- Mounting frame with mounting points for shaft trash rack and control gate. These are pre-assembled at the factory, allowing for easy and quick installation on site. This results in a significant reduction in construction effort, construction time and construction costs.

Greater marketability through scalable approach

Hydro4U’s goal is to increase the marketability of the new type of power plant and to create an overall economic concept for shaft power plants. Muhr’s scalable approach meets this goal: The modular components are designed in such a way that they can be re-dimensioned for all future power plant designs. There is no need to design parts for individual projects, which results in considerable time and cost savings.

Supply chains and manufacturing plans are also created and improved to increase marketability. Muhr has solved the new requirements for the scope of supply due to the NEXUS approach of the EU:

- The fish pass is flexibly adaptable to the respective species at the site, and the corresponding insert parts can be individualized.

- The onward transport of bedload is optimized. As a result, the riverbeds retain their natural morphology.

- The plant is prepared for climate change and can be equipped with a high and a low temperature option.

- The moving parts are not driven hydraulically, but by electric motors, meaning that oil spills cannot occur.

Proof of concept: Power plant At-Bashi, Kyrgyzstan

The feedback from others has been excellent so far. In October 2022, representatives of Orion (Kyrgyzstan) visited the Muhr Group’s headquarters in Brannenburg, Germany. Orion was extremely satisfied with the state of development. There was also praise at the general meeting of the Hydro4U project consortium in Uzbekistan in June 2022: Muhr’s work was highlighted as well thought-out and versatile.

Looking back on what has been achieved since the beginning of the project, there is unanimous agreement that the chosen approach is the right one. This will be proven with the construction of the power plant at the At-Bashi site. All products are scheduled to be shipped there by end of November 2023, with construction to start on the beginning of 2024. The final commissioning of Uzbekistan’s first shaft power plant is scheduled for end of November 2024.

Author: Fabian Böttger, MUHR Group

Images:

1) The CAD models, which are designed using Muhr’s scalable approach, can also be used for cost calculation, procurement, and manufacturing.

2) The modular components can be re-dimensioned for all future power plant designs, eliminating the need to design parts for individual projects.

Photo credits: Muhr