Modular low-head run-of-river power system with fish-friendly intake

Modular low-head run-of-river power system with fish-friendly intake

| Net Head | 2 m - 12 m |

| Discharge (per module) | 1.5 - 20.5 m³/s |

| Power Output (per module) | 20 kW - 2 MW |

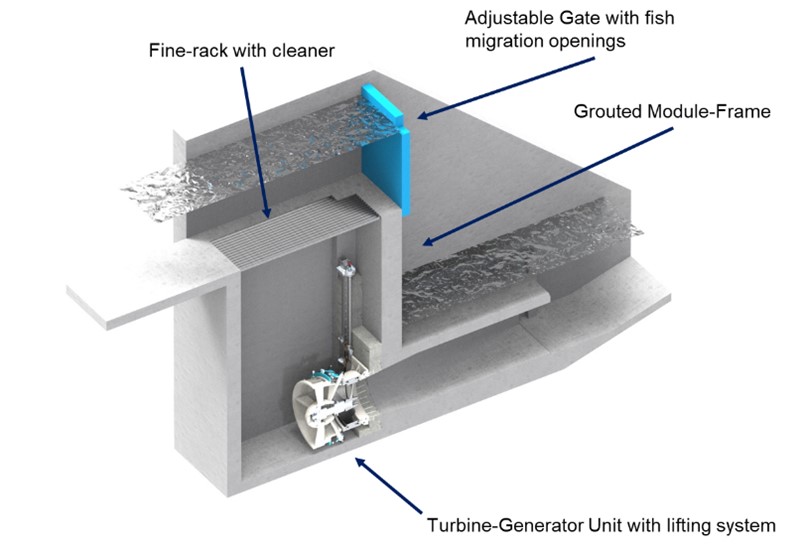

The Hydroshaft Power Solution (HSPS) is an innovative and sustainable concept that was developed at the Technical University of Munich. It is a low-head, run-of-river hydropower solution combining efficient power generation with providing ecological consistency for the river.

Watch this video to discover how the shaft power plant works:

The concept has already been applied within two commercial projects in Germany, a double-shaft implementation at Großweil, river Loisach, and a single-shaft implementation at Dietenheim, river Iller. Although these projects prove the functionality and the claimed ecological and technical advantages of the solution, it is also obvious that with conventional construction methods, it will be very difficult to enter new markets for the HSPS. The level of complexity, the amount of constructional interfaces and therefore time and cost for its implementation are too high for markets with lower returns from later operation.

Therefore, the Hydro4U partners have set the target to develop an optimised technical design of the Hydroshaft concept by turning it into a turnkey product solution and demonstrate this in Central Asia. The new design focuses on modularity and pre-fabrication to enable a fast and simple implementation also at remote sites. A large replication potential for this new solution has been identified in At-Bashi, but it is anticipated that the new design will also allow for the access to new markets all around the world.

Site & Method of selection: At-Bashy

Geo facts:

The At-Bashy demonstration site is located on the At-Bashy River southeast of Naryn City in Kyrgyzstan. This site has been identified as a demonstration site for the modular Hydroshaft Power Solution, which is being developed within the Hydro4U project. With the company Orion LLC, a competent and strong investor has been found for the joint implementation of this challenging project.

The site has been selected within the first project months, after a delegation visited several sites and met with different potential local investors in Central Asia. The local conditions at this site are tailor-made for the demonstration of the innovative modular design and erection method. An existing weir with three pressure segments offers space for up to three modules with one turbine each. The fact that the weir has to be renovated anyway increases the benefit of the project. Since the weir is used for the diversion for the irrigation of the downstream cultivated areas, the NEXUS context is also to be emphasized here. Construction of facilities for upstream and downstream fish migration will increase the positive impact from project implementation at this site. These measures will bypass the only obstacle to migration in an otherwise largely untouched section of the river – corresponding positive developments on the naturally occurring fish fauna are therefore to be expected.

The comprehensive basic design work was completed in March 2023 by TUM, which then served as the technical documentation for the subsequent authority approval procedure in Kyrgyzstan.

As the basic design had already been created in 3D and with a high level of detail, project partner ILF was able to seamlessly transfer this into the detail design stage for the construction project, and delivered the resulting technical documentation by the end of 2023.

The construction start on site is planned for August 2024. The shipment of the technical equipment and its installation is planned for the second half of 2024.

On site challenges:

Selected Updates from News & Events: